VMC-1676/1876/2076 SERIES

Advanced Precision Machining Centers

Superior Quality at an Attractive Price

Step into a world of high-quality CNC machining without breaking the bank with the Anderson VMC-1676/1876/2076 Series. This series is designed to be the go-to solution for industries dealing with wood, plastic, aluminum, or composites, offering a blend of user-friendliness, compact design, and robust performance.

With increased precision and stability, these machining centers deliver exceptional results for demanding applications across multiple industries.

Key Features

Enhanced Stability

4 Roller Linear Guideways on Y Axis provide superior stability and precision during operation, even with challenging materials.

Rapid Traverse

3 Axis Rapid Traverse at 24 m/min standard, with optional configuration of 30/30/24 m/min for increased productivity.

Cost-Effective Shipping

HQ-Container Packing system drastically reduces shipping costs while ensuring your machine arrives in perfect condition.

Advanced Lubrication

Reservoir-Type Lubricator with Bronze Tube Oil Circuit delivers consistent, reliable lubrication to all critical components.

Temperature Control

Direct Type Spindle Motor Cooling Device maintains optimal operating temperatures even during extended production runs.

User-Friendly Interface

Intuitive control system designed for ease of access and straightforward operation, reducing training time and increasing productivity.

Exceptional Performance in a Compact Design

The VMC Series, equipped with reliable FANUC control & electronics systems, offers exceptional precision and versatility. With its robust construction and advanced features, it can handle a wide variety of materials and applications.

User-Friendly Interface

Designed for ease of access and straightforward operation

Precision Engineering

Tight tolerances and exceptional repeatability

Versatile Applications

Ideal for wood, plastic, aluminum, and composite materials

Compact Footprint

Maximum performance in minimum floor space

Industry-Leading Support

Comprehensive training and technical assistance

Technical Specs

| Table Size | 1700 x 760 mm | 1900 x 760 mm | 2100 x 760 mm |

| Working Area | 1600 x 760 mm | 1800 x 760 mm | 2000 x 760 mm |

| T-Slot | 18 x 7 x 100 mm | 18 x 7 x 100 mm | 18 x 7 x 100 mm |

| Max. Table Loading Capacity | 1800 kgs | 2100 kgs | 2400 kgs |

| X/Y/Z - Axis Travel | 1600/760/700 mm | 1800/760/700 mm | 2000/760/700 mm |

| Spindle Nose To Table Surface | 140 ~ 840 mm | 140 ~ 840 mm | 140 ~ 840 mm |

| Spindle Taper | ISO 40 (ISO 50) | ISO 40 (ISO 50) | ISO 40 (ISO 50) |

| Spindle Speed | 8000 rpm (10000,12000,15000) (ISO50: 6000,8000,10000) | 8000 rpm (10000,12000,15000) (ISO50: 6000,8000,10000) | 8000 rpm (10000,12000,15000) (ISO50: 6000,8000,10000) |

| Transmission Method | Belt (Direct, Gearbox) | Belt (Direct, Gearbox) | Belt (Direct, Gearbox) |

| Spindle Motor | 11/15 kw (15/18.5) | 11/15 kw (15/18.5) | 11/15 kw (15/18.5) |

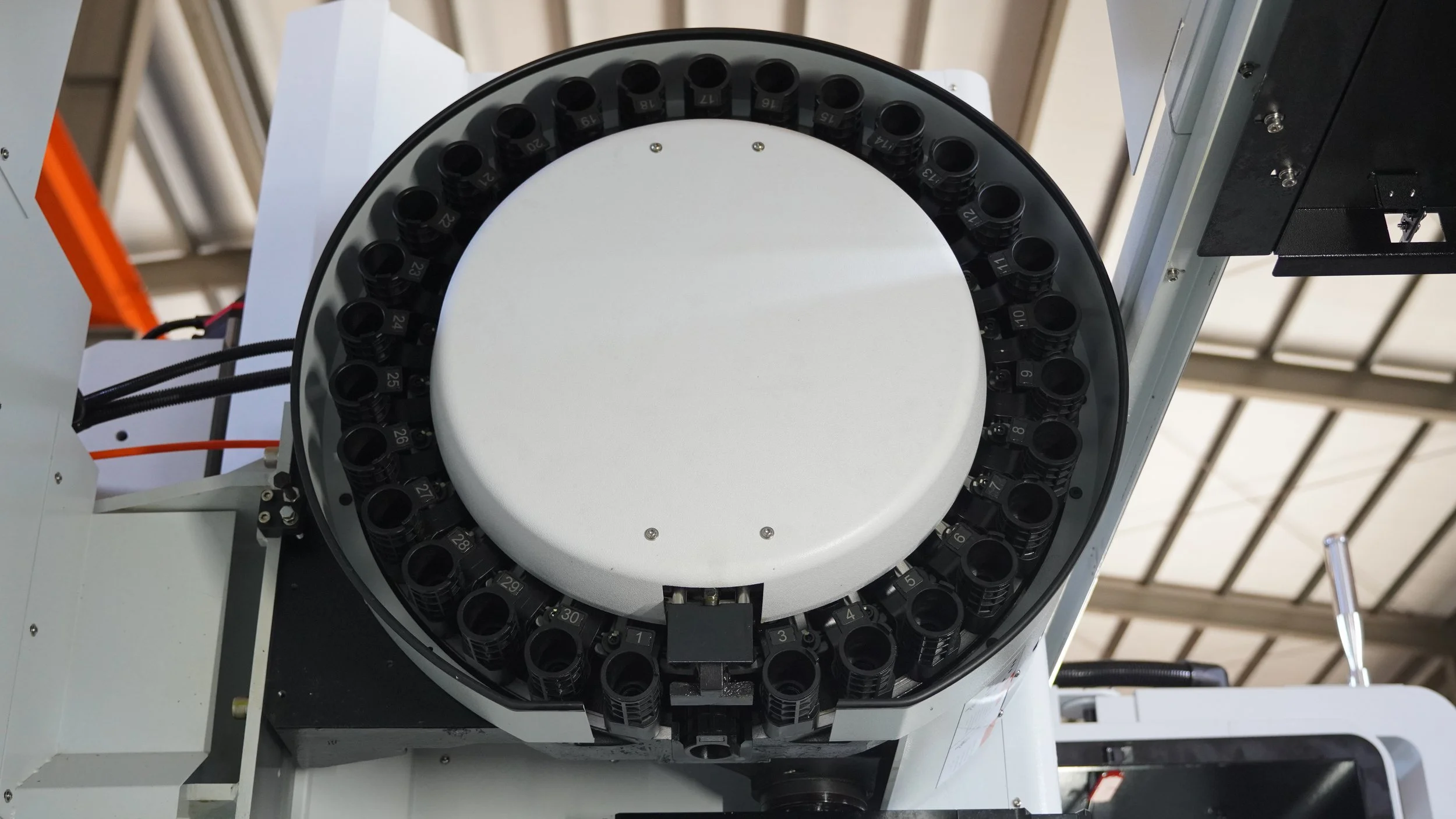

| Magazine Capacity | 24 tools (30,32,36) (ISO50: 20,24) | 24 tools (30,32,36) (ISO50: 20,24) | 24 tools (30,32,36) (ISO50: 20,24) |

| Tool Selection Method | Random | Random | Random |

| Max. Tool Diameter W/O Adjacent | Ø75 / Ø150 mm | Ø75 / Ø150 mm | Ø75 / Ø150 mm |

| Max. Tool Weight / Length | 7 kgs / 300 mm (ISO50: 15/350) | 7 kgs / 300 mm (ISO50: 15/350) | 7 kgs / 300 mm (ISO50: 15/350) |

| Tool Change Time (T-T / C-C) | T-T 2.5; C-C 4.8 sec | T-T 2.5; C-C 4.8 sec | T-T 2.5; C-C 4.8 sec |

| 3 Axis Cutting Feedrate | 12000 mm/min | 12000 mm/min | 12000 mm/min |

| 3 Axis Rapid Traverse | 24/24/24 m/min (30/30/24) | 24/24/24 m/min (30/30/24) | 24/24/24 m/min (30/30/24) |

| Coolant Tank Capacity | 480 l | 500 l | 520 l |

| Coolant Flow | 200 l/min | 200 l/min | 200 l/min |

| Dimensions (LxWxH) | 4610 x 3470 x 3190 mm | 4970 x 3470 x 3190 mm | 5440 x 3470 x 3190 mm |

| Net Weight / Gross Weight | 8700/9300 kgs | 9100/9700 kgs | 10000/10600 kgs |

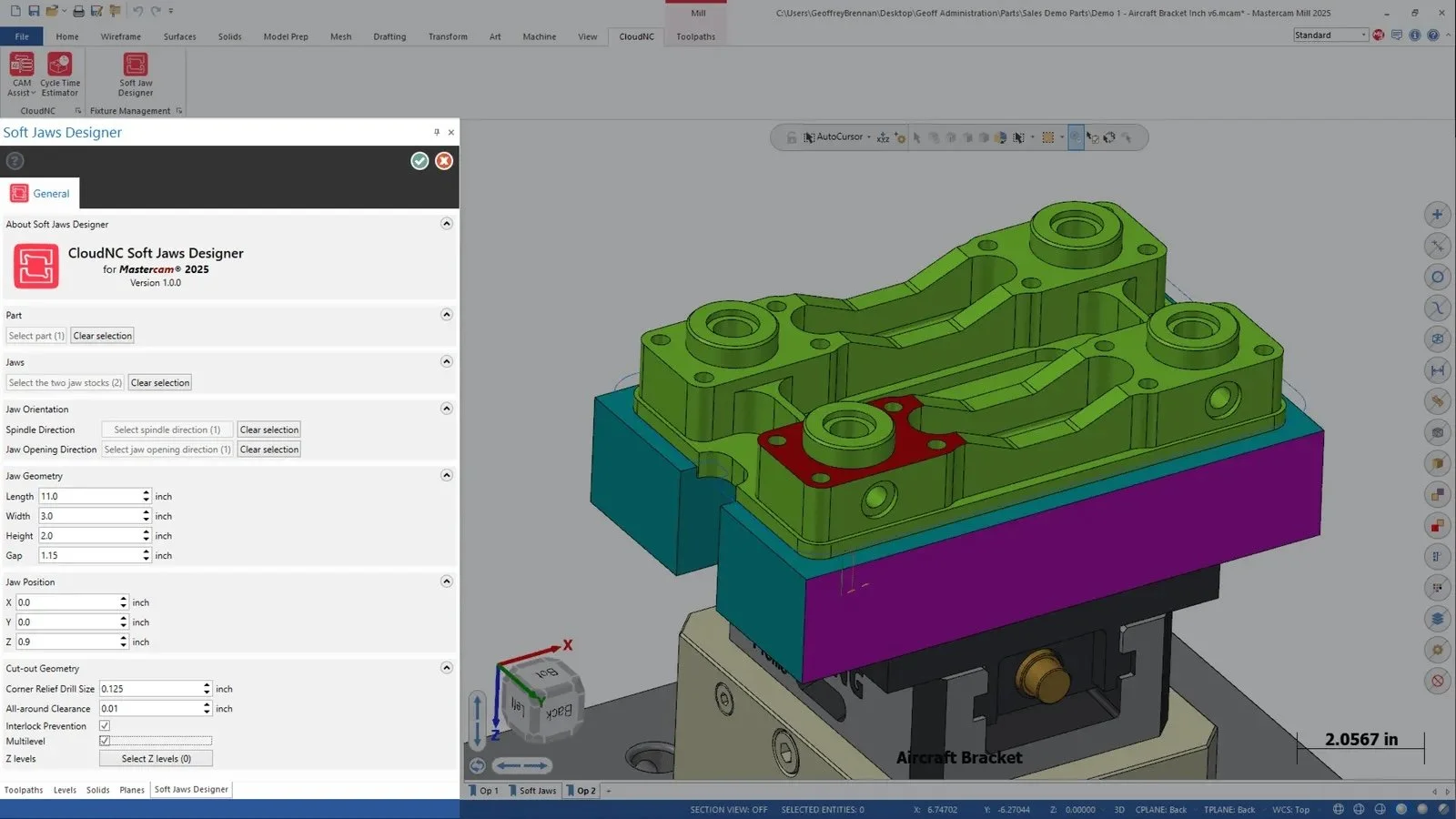

Enhance your Anderson VMC Series machines with CloudNC's AI-powered CAM automation. This third-party technology seamlessly integrates with your machine to accelerate programming and optimize machining strategies.

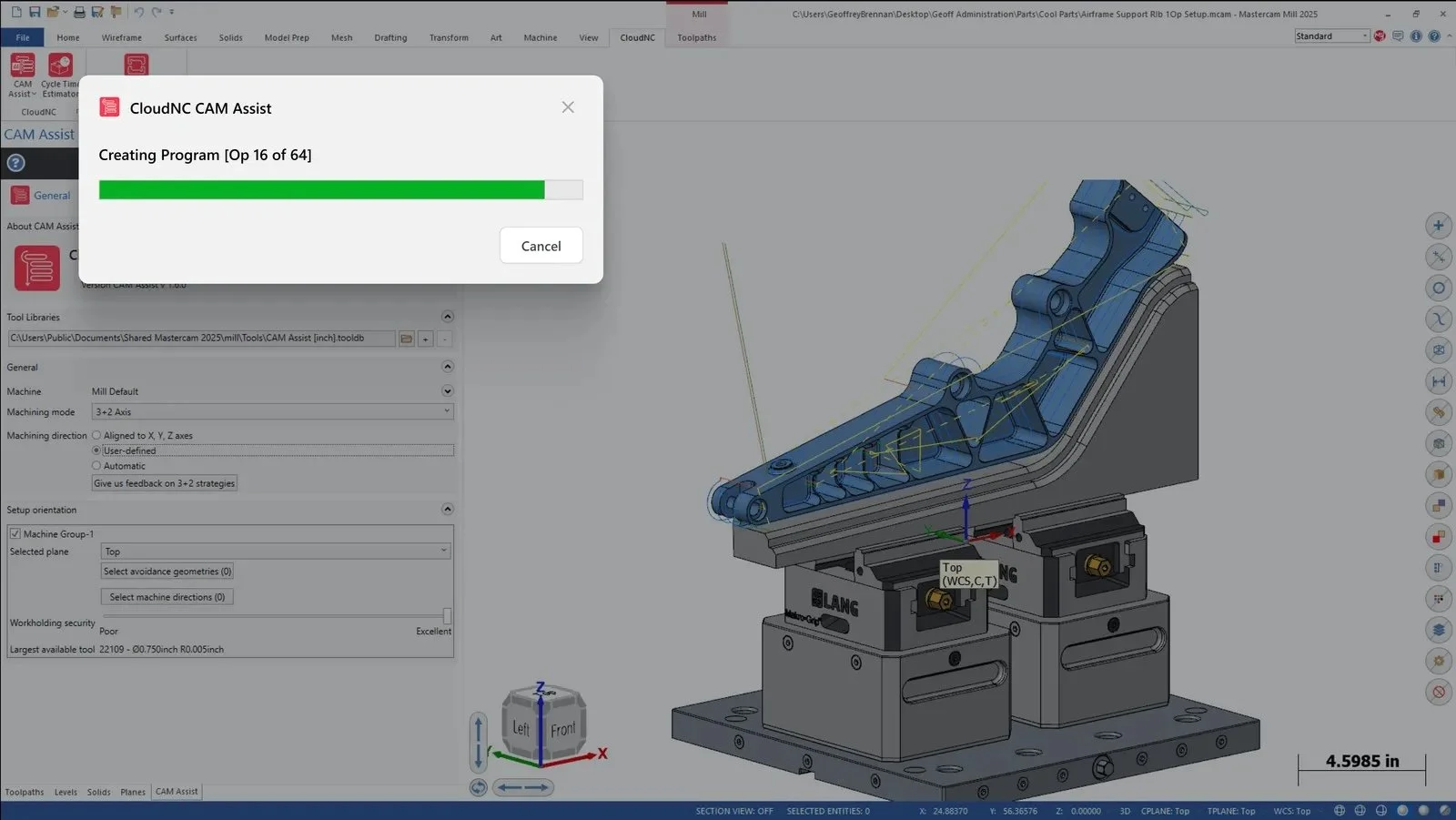

Import Your CAD File

Open your design in Mastercam with your Anderson VMC Series machine profile and workholding preferences.

Configure Settings

Select your Anderson-specific tool library, machine parameters, material type, and machining mode (3-axis or 3+2-axis).

AI Generates Toolpaths

CloudNC's AI creates optimized machining strategies, calibrated speeds and feeds for your Anderson machine, completing 80% of the programming process.

Run on Your CNC Machine

Post-process the G-Code for your specific Anderson VMC model and run the part, enjoying hours of saved programming time with optimized machining parameters.

Transform your Anderson VMC Series with advanced AI technology for faster programming, optimized performance, and smarter machining

AI-Generated Machining Workflows

Machine learning algorithms create optimal toolpaths and cutting strategies in minutes instead of hours. Let AI handle routine programming so your team can focus on higher-value work.

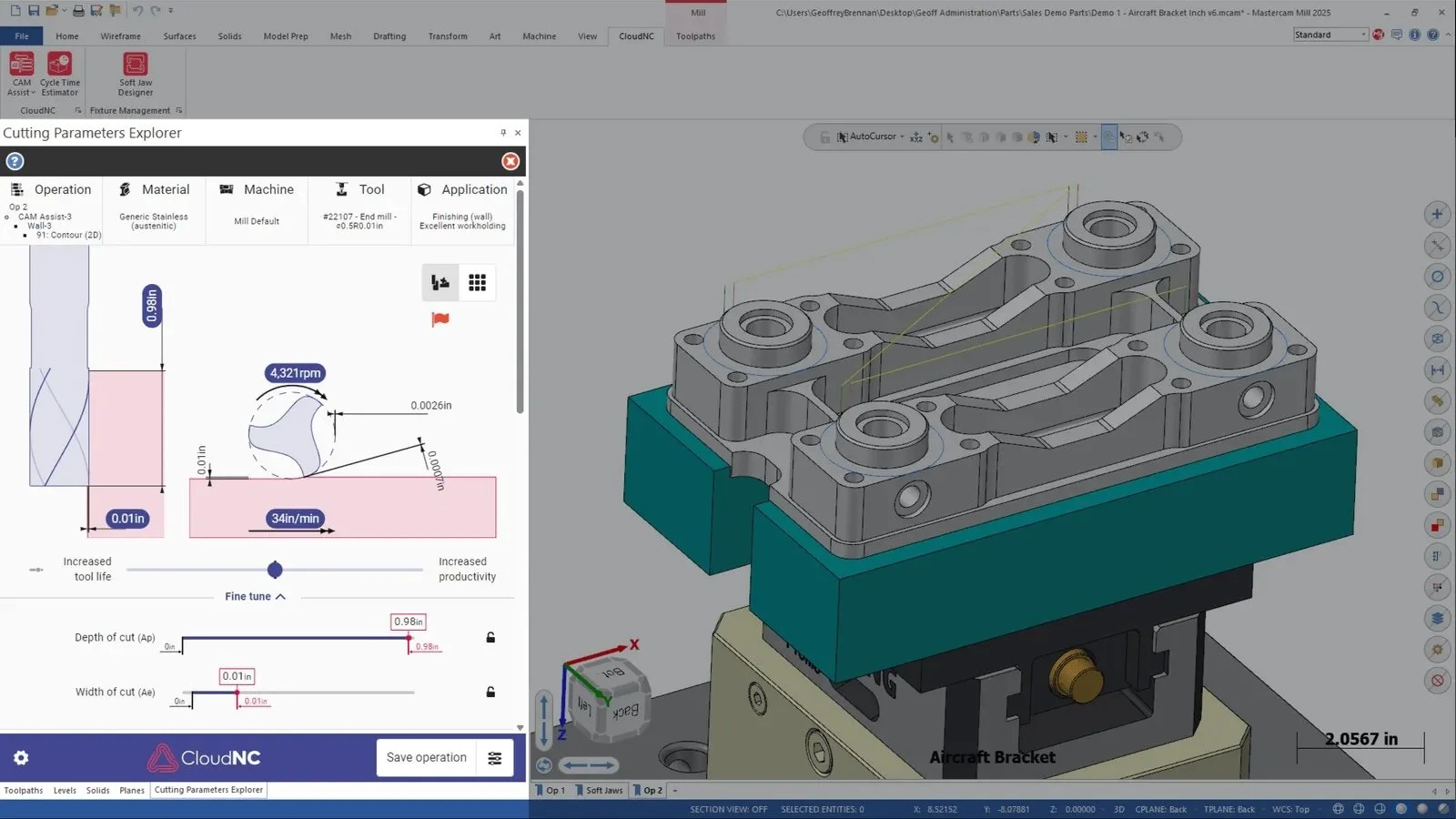

Adaptive Parameter Optimization

Physics-based AI algorithms calculate ideal cutting parameters for your specific materials and tools. Balance speed, finish quality, and tool life while maximizing your machine's capabilities.

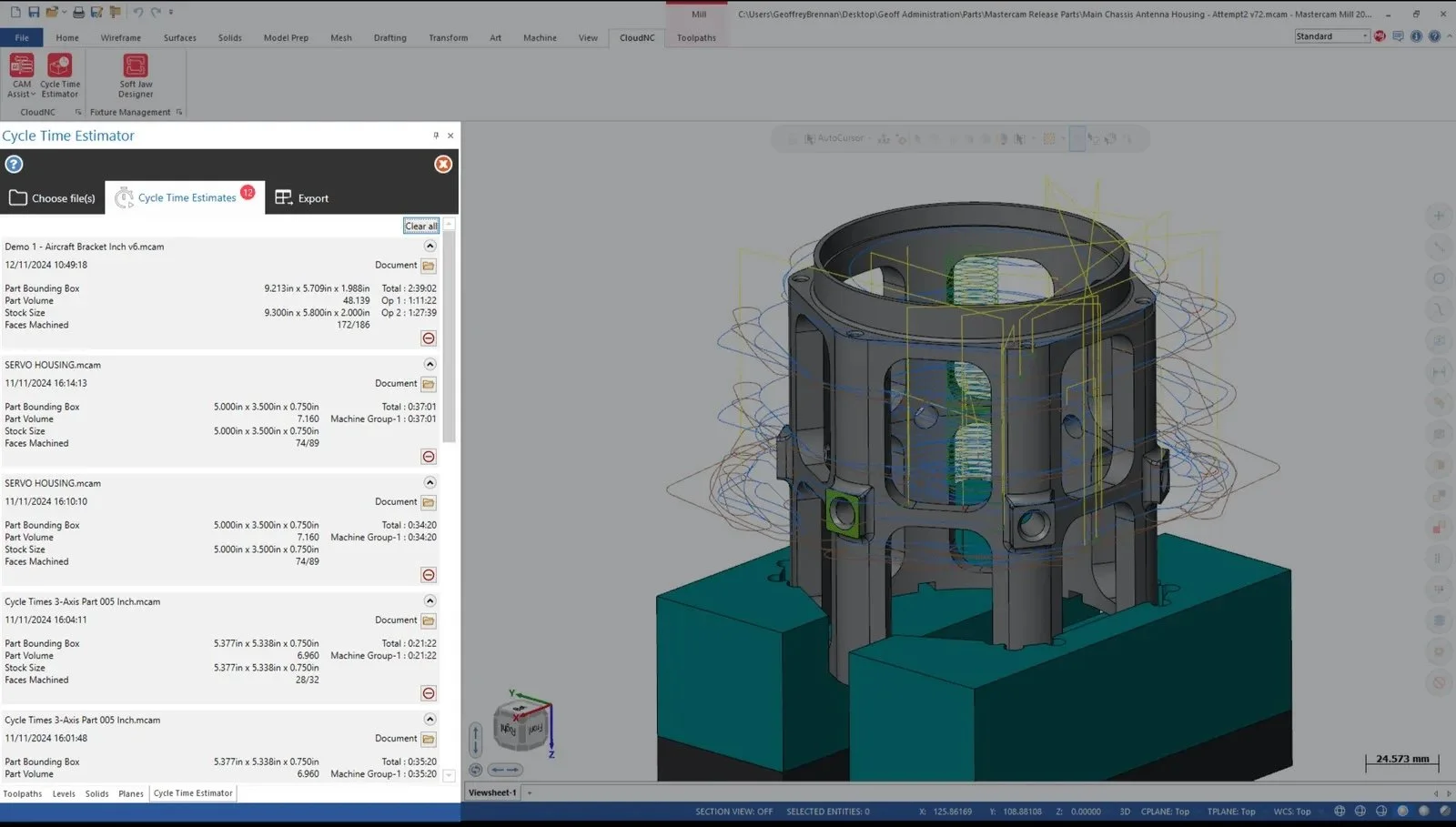

Predictive Time Analysis

AI predictive models deliver accurate machining time estimates in seconds. Create confident quotes faster, win more contracts, and improve production planning with data-driven insights.

Automated Fixture Design

Generative design algorithms create optimized workholding solutions in seconds. AI analyzes part geometry to suggest the most efficient and secure fixturing approach for complex parts.

AI-Driven Machining Strategies in Seconds

CAM Assist uses cutting-edge artificial intelligence to generate optimal 3-axis machining strategies almost instantly. Tasks that previously took hours or even days can now be completed in seconds—accelerating your programming workflow by up to 80%.

Instant Strategy Generation

Generate complex toolpaths in seconds rather than hours, dramatically reducing programming time and allowing your team to focus on higher-value tasks.

Advanced Path Optimization

The AI continuously learns from machining data to improve toolpaths, minimizing unnecessary tool movement and reducing cycle times while maintaining precision.

Precision and Efficiency Powered by AI

Experience AI-powered optimization of toolpaths, feed rates, and cutting speeds, ensuring peak performance and exceptional quality. By leveraging machine learning algorithms, CAM Assist delivers consistent results, reduces waste, and extends the life of your tooling.

AI-Optimized Parameters

Automatically calculate ideal machining parameters that balance cycle time, surface finish quality, and tool life for each specific job.

Advanced Material Intelligence

The system adapts to different materials, automatically adjusting strategies for wood, plastic, aluminum, or composites to achieve optimal results.

Tool Life Extension

Intelligent feed and speed calculations significantly extend tool life while maintaining productive cutting rates, reducing your overall tooling costs.

Instant AI-Powered Quoting Accuracy

With AI-generated instant cycle time predictions, CAM Assist significantly boosts the accuracy of your quoting process. Deliver precise and reliable estimates to your customers, increasing trust and helping you secure more projects.

Predictive Cycle Times

Get accurate machining time estimates in seconds, allowing for more competitive and profitable quotes without the risk of underestimating costs.

Material Consumption Analysis

Precisely calculate material usage, including analysis of waste material, to provide comprehensive and accurate project quotes.

Simplify Training with AI Intuition

Empower your team with CAM Assist's intuitive, user-friendly AI interface. New machinists can quickly master complex operations, dramatically shortening onboarding time and maximizing productivity from day one.

Intuitive Interface

The user-friendly design requires minimal training and allows operators of all skill levels to create professional toolpaths quickly and efficiently.

Rapid Onboarding

Get new team members productive in under an hour with an AI assistant that guides them through the process and handles complex calculations automatically.

Knowledge Retention

Capture your best machining practices within the AI system, ensuring consistency even as team members change and preserving your company's expertise.

Seamless Integration for Immediate Impact

CAM Assist effortlessly complements the advanced capabilities of your Anderson VMC machines, requiring minimal setup. Its AI technology easily integrates into your current processes, helping you leverage your machine's full potential immediately.

Compatible with Leading CAM Software

Integrates with popular CAM systems including Mastercam, ensuring compatibility with your existing workflows and tooling libraries.

Secure Cloud Implementation

The solution is hosted on AWS GovCloud (US) with SOC 2 Type 1 and Cyber Essentials Plus certification for maximum security and reliability.

Take Your Production to the Next Level

Our team is always ready to assist you with any questions or custom requirements you may have. Don't hesitate to reach out to us for more information.